Ultimate Guide to Epoxy Flooring in Egypt 2025 – 2026

Epoxy Flooring

Introduction to Epoxy Flooring

Between 2025 and 2026, epoxy flooring has become the leading trend in Egypt’s industrial and commercial finishing sector. It is not just an alternative to ceramic or ordinary concrete but a practical solution that combines strength, durability, and a modern look. That’s why it has become the first choice for factories, garages, warehouses, medical centers, and commercial showrooms.

Epoxy Flooring Installation

The installation process goes through several precise stages:

- Preparing the surface by cleaning and repairing cracks in the concrete.

- Applying a primer layer to ensure proper adhesion.

- Pouring the epoxy material and spreading it evenly.

- Adding color effects or guide markings for factories and garages if required.

- Finishing with a transparent protective coat for extra durability.

Epoxy Wall Coating

Using epoxy for wall coating provides:

- A strong and easy-to-clean surface.

- Resistance to moisture and heat.

- Excellent insulation for industrial walls in factories and warehouses.

- A professional and practical appearance for commercial spaces.

Epoxy for Outdoor Floors

- Withstands weather conditions (rain, thermal changes).

- Resistant to wear and tear caused by vehicle traffic.

- Ideal for garages, loading, and unloading areas.

- Supports the addition of ground markings and traffic lines.

⚠️ Important Note: Standard epoxy does not withstand direct sunlight (UV rays) and may discolor or crack. The solution is to use UV-Resistant Epoxy systems or alternatives like Polyurethane (PU) for exposed outdoor areas.

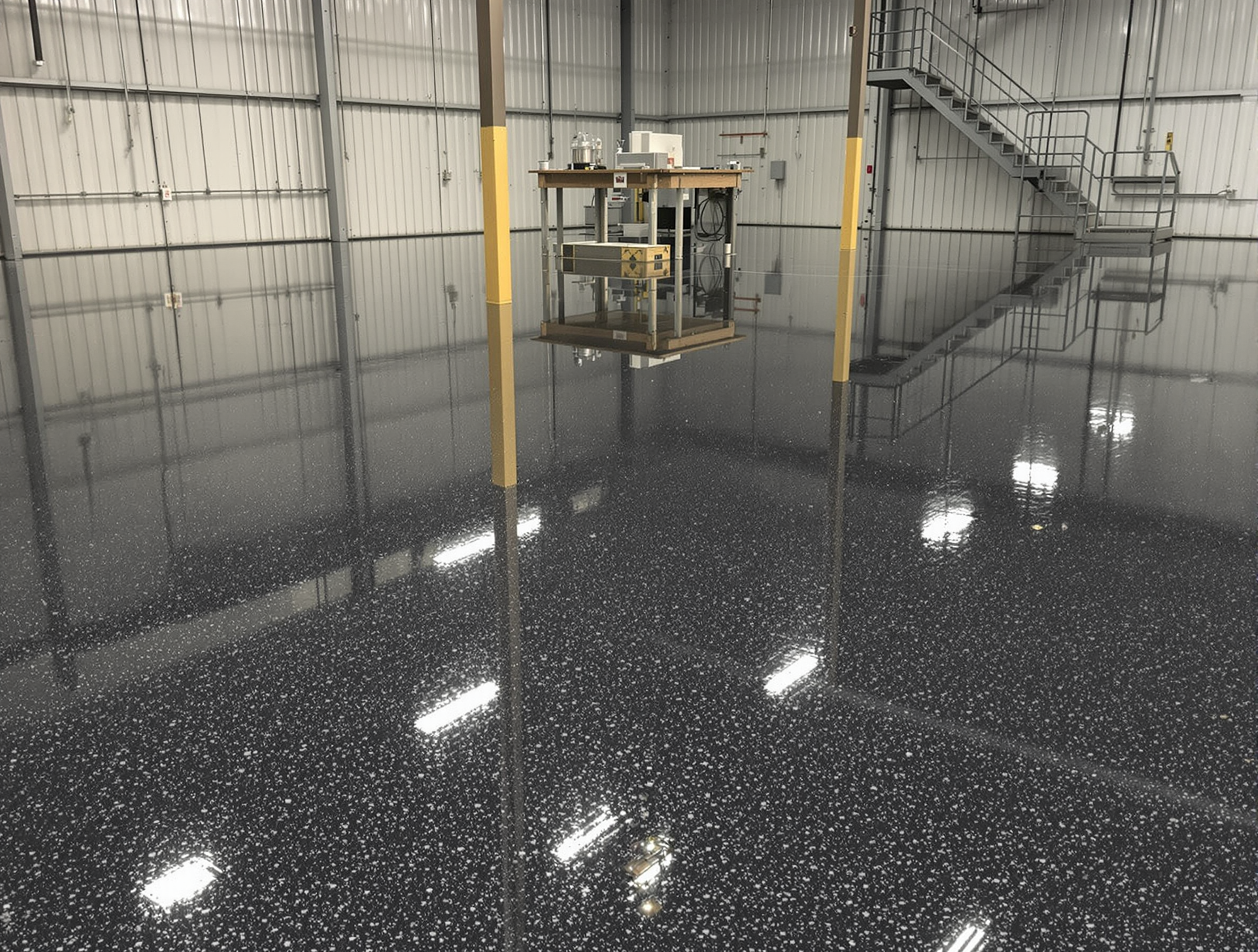

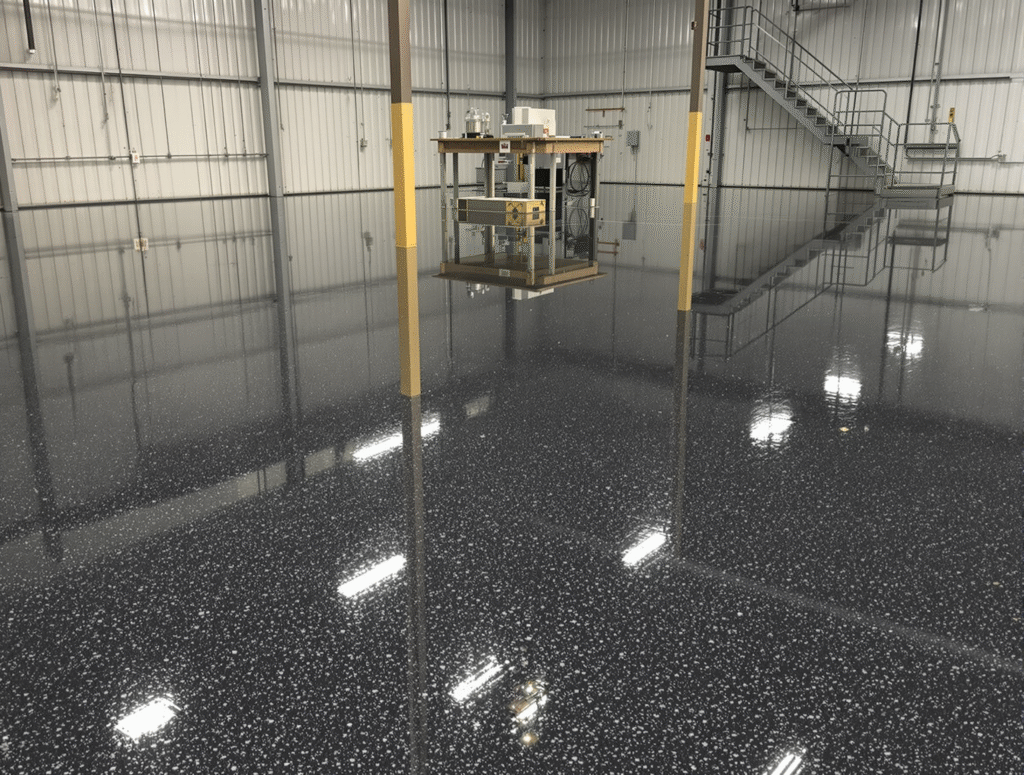

Self-Leveling Epoxy

- Perfect for renovating old concrete floors in factories.

- Provides a smooth surface that can withstand heavy equipment movement.

- Slip-resistant and easy to clean.

- Reduces the need for frequent maintenance.

Best Types of Epoxy Flooring

- Industrial Epoxy: Handles heavy loads, oils, and chemicals.

- Anti-Slip Epoxy: Suitable for garages and industrial kitchens.

- Decorative Epoxy: Used in malls, showrooms, and commercial centers.

- 3D Epoxy: Designed for luxurious spaces that require unique visual effects.

3D Epoxy Flooring

- Widely used in showrooms and commercial centers.

- Adds a visually appealing look that reflects brand identity.

- Covered with a strong transparent topcoat to withstand heavy usage.

Advantages of Epoxy Flooring

- Long lifespan (10 – 15 years).

- High resistance to stains, oils, and chemicals.

- Strong enough to withstand forklifts and heavy machinery.

- Resistant to moisture and heat.

- Easy to clean and maintain in industrial environments.

- Allows adding directional markings in garages and warehouses.

Epoxy Prices in Egypt 2025 – 2026 (Practical Examples)

Prices vary depending on the type, design, area, and the contractor’s expertise:

- Industrial Epoxy (single color): 250 – 300 EGP/m²

- Decorative Epoxy (malls/showrooms): 350 – 450 EGP/m²

- 3D Epoxy (luxury showrooms): 700 – 1200 EGP/m²

- Self-Leveling Epoxy (factories/warehouses): 400 – 600 EGP/m²

🔑 Practical Example:

- A factory with an area of 1,000 m² requiring self-leveling epoxy at an average of 450 EGP/m² = 450,000 EGP including installation.

- A car garage with an area of 500 m² using industrial epoxy resistant to oils at an average of 300 EGP/m² = 150,000 EGP.

Factors Determining Final Cost

- Total area (larger areas reduce cost per square meter).

- Type of epoxy (industrial – decorative – 3D).

- Thickness and number of layers required.

- Condition of the existing floor (whether it needs repairs).

- Additional requirements (organizational lines, floor markings).

EG CORE’s Role in Epoxy Applications

EG CORE is one of Egypt’s leading engineering solutions companies specializing in industrial flooring. Its role in epoxy application includes:

- Repairing and treating concrete before installation.

- Using injection systems to fix cracks and structural defects.

- Providing waterproofing solutions for factories and warehouses.

- Executing floors capable of handling heavy machinery and forklifts.

- Adding directional lines in garages and storage facilities.

Thanks to its expertise, EG CORE offers a comprehensive service that starts from infrastructure and ends with a high-quality finish.

EG CORE Quality

EG CORE is distinguished by its high-quality standards through:

- Using certified imported raw materials.

- Specialized teams for large-scale industrial projects.

- Commitment to international quality specifications.

- On-time project delivery.

- Long-term written warranty on executed work.

Here, quality means: Durability + Continuity + Professional Appearance that meets the needs of companies and factories.

💡 Conclusion

Epoxy flooring in Egypt (2025 – 2026) has become the ideal solution for companies, factories, and garages. It provides high durability, resistance to oils and chemicals, and a modern organized look. With EG CORE, you get professional execution and guaranteed quality—making your flooring investment a strategic addition to your company’s infrastructure. Check out our facebook page updated Epoxy information when it’s available.